In the realm of electronic manufacturing and prototyping, the FR4 PCB board stands as a cornerstone material, offering unparalleled reliability and versatility for a wide range of applications. These boards, primarily composed of glass-reinforced epoxy laminate, are essential for creating robust and high-performance circuit solutions. As technology continues to advance, the demand for specialized PCB boards, including those made from FR4, has surged.

FR4 PCB board is a critical component in the electronics industry, known for its excellent electrical insulation, mechanical strength, and thermal stability. These boards are used in various applications, from simple hobbyist projects to complex industrial machinery. To better understand the landscape of FR4 PCB board, it is important to explore related trending search terms such as

PCB FR4 side copper,

PCB with copper for boards,

copper clad FR4,

double side prototyping PCB,

breadboard prototype,

bread PCB, board FR4,

copper cladded board FR4,

FR4 two layer PCB, and board for assembly electronics.

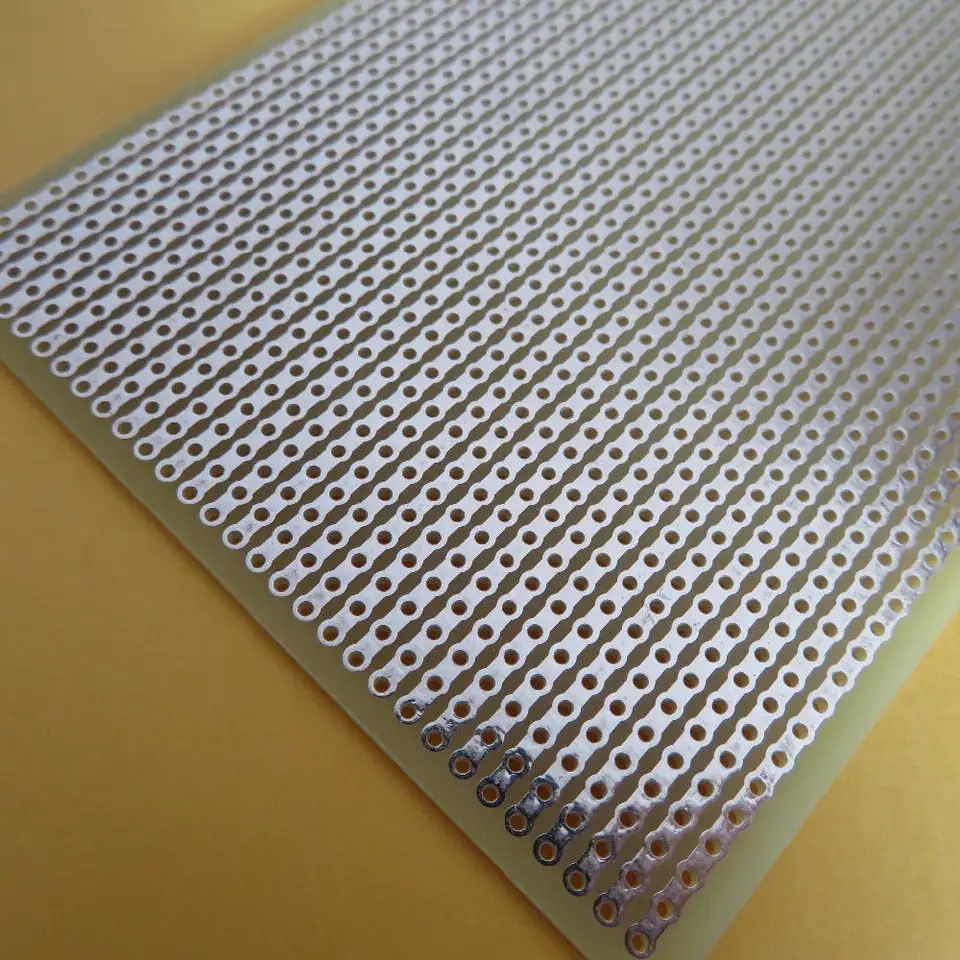

When discussing PCBs, the term FR4 side copper refers to the copper coating on the surface of the FR4 board, which is crucial for conducting electricity and forming the traces of the circuit. PCB with copper for boards further emphasizes the importance of the copper layer in providing conductive paths. Copper clad FR4 is another term that highlights the copper-coated nature of the board, indicating its suitability for high-performance applications.

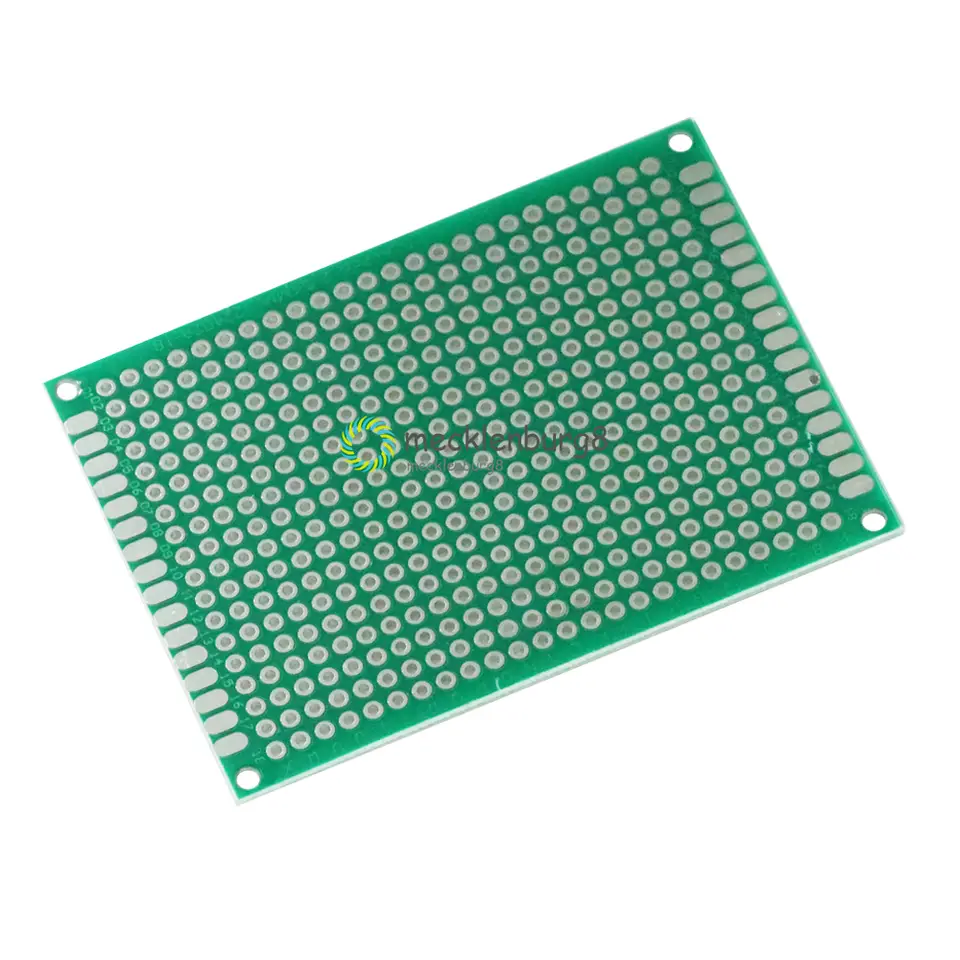

Double side prototyping PCB refers to a specific type of FR4 board designed for prototyping, offering a cost-effective and flexible solution for testing and validating designs. Breadboard prototype and bread PCB are terms used for prototyping boards that mimic the functionality of a breadboard, allowing for easy connection and testing of components without soldering. Board FR4 and copper cladded board FR4 reiterate the material composition and its applications, while FR4 two layer PCB points to a board with copper on both sides, ideal for complex circuit designs.

Lastly, board for assembly electronics underscores the broader application of FR4 boards in electronics assembly, emphasizing their role in creating functional and reliable electronic devices. These related terms collectively provide a comprehensive view of the versatility and importance of FR4 PCB boards in modern electronics manufacturing and prototyping.

FR4 PCB boards are essential components in the electronics industry, known for their robustness, reliability, and versatility. These boards are made from a combination of glass-reinforced epoxy laminate, which provides excellent electrical insulation, mechanical strength, and thermal stability. Understanding the features and functions of FR4 PCB boards is crucial for anyone involved in electronics manufacturing and prototyping.

FR4 PCB boards are characterized by their excellent electrical properties, making them suitable for a wide range of applications. The key features include:

1. Electrical Insulation: FR4 boards offer superior electrical insulation, ensuring that the circuit remains stable and protected from short circuits and other electrical failures.

2. Mechanical Strength: They are incredibly durable and can withstand physical stress, making them ideal for both industrial and consumer electronics.

3. Thermal Stability: FR4 boards can handle a wide range of temperatures, providing reliable performance in both hot and cold environments.

4. Cost-Effectiveness: FR4 boards are relatively inexpensive compared to other high-end PCB materials, making them a popular choice for both small-scale and large-scale production.

FR4 PCB boards are used in various functions, including:

1. Prototyping: FR4 boards, such as double-sided prototyping PCBs and breadboard prototypes, are ideal for testing and validating designs. These boards, often referred to as bread PCBs or breadboard prototypes, allow for easy connection and testing of components without soldering.

2. Assembly: Boards for assembly electronics are used in the final stages of electronics production, ensuring that components are securely and correctly placed on the board.

3. High-Performance Applications: Double-sided copper clad FR4 boards are perfect for complex circuit designs, offering two layers of copper for increased conductive paths and improved signal integrity.

FR4 PCB boards come in various forms and configurations, including:

1. PCB FR4 Side Copper: This refers to the copper coating on the surface of the FR4 board, crucial for conducting electricity and forming the traces of the circuit.

2. Copper Clad FR4: This term highlights the copper-coated nature of the board, indicating its suitability for high-performance applications.

3. Double-Sided PCB: Boards with copper on both sides, ideal for complex circuit designs.

4. Board for Assembly Electronics: These boards are specifically designed for the final stages of electronics assembly, ensuring reliability and functionality.

Related trending search terms include PCB FR4 side copper, FR4 copper clad, and board single side copper PCB plate, highlighting the importance of the copper layer in these boards. Copper plate for PCB and board circuit copper further emphasize the role of copper in FR4 PCB boards. PCB assembly board and double-sided copper clad FR4 are terms that highlight the dual-sided nature of these boards, which is crucial for advanced circuit designs.

The best-selling products in this category include integrated circuits, double-sided PCBs, and replacement parts and terminal blocks. These products are often used in conjunction with FR4 PCB boards to enhance their functionality and reliability.

In conclusion, FR4 PCB boards are versatile and reliable components that are essential for electronics manufacturing and prototyping. Whether you need a simple prototyping board or a high-performance circuit board, FR4 PCB boards provide the necessary electrical insulation, mechanical strength, and thermal stability to ensure your electronics projects are successful.

Choosing the right FR4 PCB board is crucial for ensuring the success of your electronic project. Whether you are a hobbyist, a professional engineer, or a manufacturer, selecting the appropriate FR4 PCB board can significantly impact the performance and reliability of your circuit. Here are some key factors to consider when choosing an FR4 PCB board:

1. Application Requirements: Determine the specific needs of your project. For prototyping and simple hobbyist projects, a double-sided prototyping PCB or a breadboard prototype might suffice. For more complex applications, such as industrial electronics or high-performance circuits, a double-sided copper clad FR4 board is essential.

2. Material Specifications: FR4 PCB boards are known for their robust electrical insulation, mechanical strength, and thermal stability. Ensure that the board you choose meets these specifications. Look for boards that are compliant with standards like RoHS (Restriction of Hazardous Substances) and have a suitable thickness (commonly 1.6mm, 1.8mm, or 2.0mm).

3. Size and Shape: The size and shape of the board should match your project's dimensions. For instance, a 7x9cm (70x90mm) board is perfect for breadboard prototypes and prototyping PCBs, while larger boards are necessary for more extensive circuit assemblies.

4. Copper Cladding: The copper cladding on the board is crucial for conducting electricity and forming traces. For prototyping, a double-sided copper clad FR4 board is ideal. This board provides more conductive paths, enhancing signal integrity and reducing the risk of shorts.

5. Layer Configuration: Consider the layer configuration based on your project's complexity. Single-layer boards are simpler and more cost-effective, while double-layer boards offer more flexibility and can handle more complex circuits.

6. Manufacturing Quality: Choose a manufacturer known for high-quality PCB production. Look for boards that have a smooth surface and precise etching. High-quality boards ensure reliable connections and reduced chances of manufacturing defects.

7. Budget: FR4 PCB boards come in various price ranges. Determine your budget and choose a board that offers the necessary features without compromising on quality.

Based on the related trending search terms and best-selling products, here are some specific recommendations:

- FR4 94V0 RoHS Multilayer PCB Board Assembly: This product is ideal for complex circuit assemblies and multilayer PCBs. Its compliance with RoHS standards ensures environmental safety and reliability.

- 5PCS Prototype Solderless PCB Board: This double-sided prototyping PCB is perfect for hobbyists and small-scale prototyping. It is universal and can be used for a wide range of projects, offering flexibility and ease of use.

- 20x30 15x20 12x18 10x20 10x15 7x10 5x7 cm FR4 Double Side Copper Clad Plate: This DIY PCB kit is suitable for custom circuit board assembly. It provides double-sided copper cladding, which is essential for more advanced circuit designs.

- 10pcs/lot Single Side 1015 FR4 FR-4 Glass Fiber Blank Copper Clad Printed Circuit Board: This single-sided board is ideal for simple projects and prototypes. It is universal and can be used for a variety of applications, offering a cost-effective solution.

When choosing an FR4 PCB board, consider the application requirements, material specifications, size, and copper cladding. By carefully evaluating these factors, you can select the right FR4 PCB board to ensure the success of your electronic project.

Understanding FR4 PCB Boards: A Comprehensive Guide

FR4 PCB boards are fundamental components in the electronics industry, offering unparalleled reliability, durability, and versatility for a wide range of applications. These boards, primarily composed of glass-reinforced epoxy laminate, are essential for creating robust and high-performance circuit solutions. Understanding the features, functions, and selection criteria of FR4 PCB boards is crucial for anyone involved in electronics manufacturing and prototyping.

Features and Functions of FR4 PCB Boards

FR4 PCB boards are renowned for their excellent electrical insulation, mechanical strength, and thermal stability. They are used in various applications, from simple hobbyist projects to complex industrial machinery. Key features include:

- Electrical Insulation: Provides superior insulation, ensuring stable and protected circuits.

- Mechanical Strength: Extremely durable and resistant to physical stress, making them suitable for both industrial and consumer electronics.

- Thermal Stability: Can handle a wide range of temperatures, ensuring reliable performance in various environments.

- Cost-Effectiveness: Relatively inexpensive compared to other high-end PCB materials, making them a popular choice for both small-scale and large-scale production.

Choosing the Right FR4 PCB Board

Selecting the appropriate FR4 PCB board is crucial for the success of your electronic project. Here are some key factors to consider:

1. Application Requirements: Determine the specific needs of your project. For prototyping and simple hobbyist projects, a double-sided prototyping PCB or a breadboard prototype might suffice. For more complex applications, a double-sided copper clad FR4 board is essential.

2. Material Specifications: Ensure that the board meets the necessary electrical insulation, mechanical strength, and thermal stability standards. Look for boards compliant with RoHS standards and with a suitable thickness (commonly 1.6mm, 1.8mm, or 2.0mm).

3. Size and Shape: Choose a board that matches your project’s dimensions. A 7x9cm (70x90mm) board is ideal for breadboard prototypes and prototyping PCBs, while larger boards are necessary for more extensive circuit assemblies.

4. Copper Cladding: The copper cladding is crucial for conducting electricity and forming traces. For prototyping, a double-sided copper clad FR4 board provides more conductive paths, enhancing signal integrity and reducing the risk of shorts.

5. Layer Configuration: Consider the layer configuration based on your project's complexity. Single-layer boards are simpler and more cost-effective, while double-layer boards offer more flexibility and can handle more complex circuits.

6. Manufacturing Quality: Choose a manufacturer known for high-quality PCB production. Look for boards with a smooth surface and precise etching. High-quality boards ensure reliable connections and reduced chances of manufacturing defects.

7. Budget: FR4 PCB boards come in various price ranges. Determine your budget and choose a board that offers the necessary features without compromising on quality.

Related Trending Search Terms

Related trending search terms include:

- PCB FR4 side copper: Refers to the copper coating on the surface of the FR4 board, crucial for conducting electricity and forming traces.

- PCB with copper for boards: Emphasizes the copper layer's importance in providing conductive paths.

- Copper clad FR4: Highlights the copper-coated nature of the board, suitable for high-performance applications.

- Double side prototyping PCB: Ideal for testing and validating designs, offering a cost-effective and flexible solution.

- Breadboard prototype: Mimics the functionality of a breadboard, allowing for easy connection and testing of components without soldering.

- Board FR4: General term for FR4 boards, highlighting their material composition and applications.

- Copper cladded board FR4: Emphasizes the copper cladding, indicating its suitability for advanced circuit designs.

- FR4 two layer PCB: Suitable for complex circuit designs, offering two layers of copper for increased conductive paths and improved signal integrity.

- Board for assembly electronics: Specifically designed for the final stages of electronics assembly, ensuring reliability and functionality.

Best-Selling Products

The best-selling products include:

- FR4 94V0 RoHS Multilayer PCB Board Assembly: Ideal for complex circuit assemblies and multilayer PCBs, ensuring environmental safety and reliability.

- 5PCS Prototype Solderless PCB Board: Perfect for hobbyists and small-scale prototyping, offering flexibility and ease of use.

- 20x30 15x20 12x18 10x20 10x15 7x10 5x7 cm FR4 Double Side Copper Clad Plate: Suitable for custom circuit board assembly, providing double-sided copper cladding for advanced designs.

- 10pcs/lot Single Side 1015 FR4 FR-4 Glass Fiber Blank Copper Clad Printed Circuit Board: Ideal for simple projects and prototypes, offering a cost-effective solution.

In conclusion, FR4 PCB boards are versatile and reliable components essential for electronics manufacturing and prototyping. By carefully evaluating the application requirements, material specifications, size, and copper cladding, you can choose the right FR4 PCB board to ensure the success of your electronic project.